Flexibility and Durability

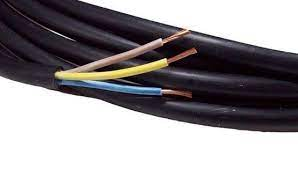

Rubber cables are known for their exceptional flexibility and durability, making them suitable for a wide variety of industrial applications. Whether they are used in heavy machinery, conveyor systems, or exposed outdoor environments, rubber cable can withstand bending, twisting, and other forms of mechanical stress without sacrificing performance. This flexibility not only simplifies installation and maintenance but also reduces the risk of damage, ensuring reliable power transmission and signal integrity in demanding industrial environments.

Resistance to Harsh Environments

Industrial settings often expose cables to extreme temperatures, moisture, chemicals, and mechanical abrasion, all of which can significantly impact their performance and longevity. Rubber cables are specifically designed to withstand these harsh environmental conditions, offering excellent resistance to oil, water, sunlight, and a wide range of chemicals. This resistance ensures that rubber cables maintain their integrity and insulation properties, even in the most challenging industrial environments, thereby minimizing the risk of downtime and maintenance costs associated with cable failures.

Electrical and Mechanical Performance

In industrial applications, consistent electrical and mechanical performance is crucial for maintaining operational efficiency and safety. Rubber cables excel in this regard, delivering stable electrical conductivity and insulation properties, even in high-voltage and high-temperature environments. Additionally, their robust construction and resistance to abrasion and impact ensure reliable mechanical performance, minimizing the risk of electrical faults or short circuits that could compromise industrial operations and pose safety hazards.

Flame Retardancy and Safety Compliance

Safety is paramount in industrial environments, and the use of flame-retardant cables is essential to minimize the risk of fire-related incidents. Rubber cables typically feature flame-retardant properties that meet industry standards and regulatory requirements, making them a safe and reliable choice for industrial applications. By using rubber cables with superior flame-retardant properties, industrial facilities can enhance the overall safety of their operations and minimize the potential impact of fire-related accidents.

Cost-Effectiveness and Longevity

Investing in high-quality rubber cables can result in long-term cost savings for industrial facilities. Their exceptional durability and resistance to environmental factors contribute to an extended lifespan, reducing the frequency of cable replacements and maintenance expenses. Additionally, the reliable performance of rubber cables minimizes operational disruptions, contributing to increased productivity and overall cost-effectiveness in industrial operations. By choosing rubber cables, industrial facilities can benefit from a cost-effective solution that offers long-term reliability and performance.

the benefits of using rubber cables in industrial applications are undeniable. From their flexibility and durability to their resistance to harsh environments and compliance with safety standards, rubber cables offer a wide array of advantages that can positively impact the efficiency, safety, and cost-effectiveness of industrial operations. By incorporating rubber cables into their infrastructure, industrial facilities can ensure reliable power transmission, signal integrity, and operational continuity, ultimately enhancing their overall performance and success.

1 Comments

Znergy Cable stands as a premier rubber cable suppliers, offering a diverse range including Copper Armored Cable, fire retardant cable, Type 450 Cable, and various electrical cable solutions. Renowned for our commitment to excellence, we pride ourselves on manufacturing cables that meet stringent standards for durability, safety, and performance. With a focus on innovation and customer satisfaction, Znergy Cable continuously strives to deliver reliable and efficient cable solutions to meet the evolving needs of industries worldwide.

ReplyDelete